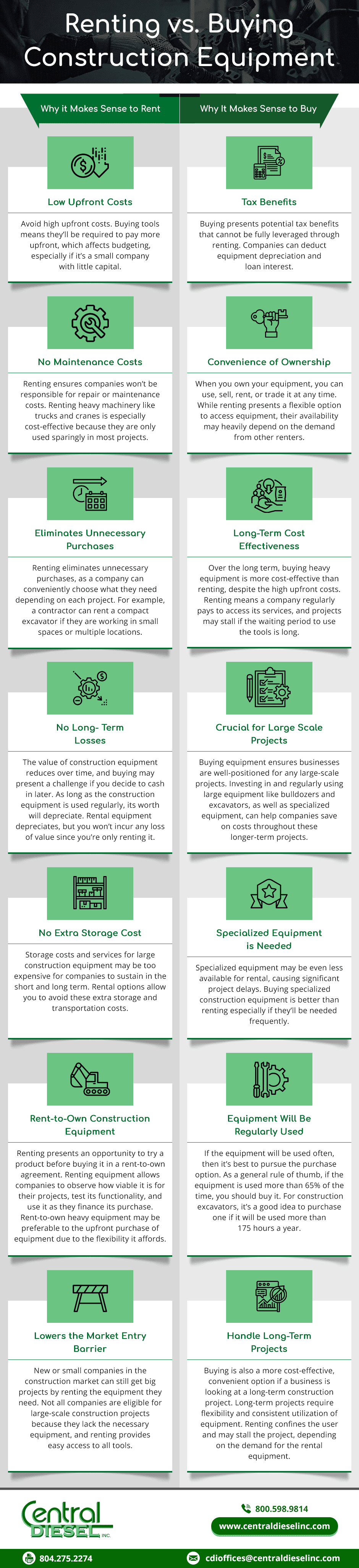

Benefits of Renting vs. Buying Construction Equipment

Leave a CommentTo complete their construction projects, construction companies usually have the option to either rent or buy the necessary equipment. The decision to buy vs. rent construction equipment is important, as it will impact the project’s management, budget, and construction plans. The decision also depends on the complexity and scope of the project itself.

Depending on the company’s short- and long-term construction goals, renting and buying each has its own advantages and disadvantages. This post outlines the benefits of renting equipment and when it’s best to buy.

Benefits of Renting Construction Equipment

Renting construction equipment has become popular among construction companies. The benefits of renting include:

Low Upfront Costs

Businesses prefer to rent construction equipment to avoid high upfront costs. Buying tools means they’ll be required to pay more upfront, which affects budgeting, especially if it’s a small company with little capital.

No Maintenance Costs

Renting equipment ensures companies won’t be responsible for repair or maintenance costs. Renting heavy machinery like trucks and cranes is especially cost-effective because they are only used sparingly in most projects.

Eliminates Unnecessary Purchases

Renting eliminates unnecessary purchases, as a company can conveniently choose what they need depending on each project. For example, a contractor can rent a compact excavator if they are working in small spaces or multiple locations.

No Extra Storage Cost

Storage costs and services for large construction equipment may be too expensive for companies to sustain in the short and long term. Rental options allow you to avoid these extra storage and transportation costs.

No Long-Term Losses

The value of construction equipment reduces over time, and buying may present a challenge if you decide to cash in later. As long as the construction equipment is used regularly, its worth will depreciate. Rental equipment depreciates, but you won’t incur any loss of value since you’re only renting it.

Rent-To-Own Construction Equipment

Renting presents an opportunity to try a product before buying it in a rent-to-own agreement. Renting equipment allows companies to observe how viable it is for their projects, test its functionality, and use it as they finance its purchase. Rent-to-own heavy equipment may be preferable to the upfront purchase of equipment due to the flexibility it affords.

Lowers the Market Entry Barrier

New or small companies in the construction market can still get big projects by renting the equipment they need. Not all companies are eligible for large-scale construction projects because they lack the necessary equipment, and renting provides easy access to all tools.

Benefits of Buying Construction Equipment

Some construction companies may prefer to own their construction equipment instead of renting. Some of the benefits of buying equipment include:

Long-Term Cost-Effectiveness

Over the long term, buying heavy equipment is more cost-effective than renting, despite the high upfront costs. Renting means a company regularly pays to access its services, and projects may stall if the waiting period to use the tools is long.

Tax Benefits

Buying presents potential tax benefits that cannot be fully leveraged through renting. Companies can deduct equipment depreciation and loan interest.

Convenience of Ownership

When you own your equipment, you can use, sell, rent, or trade it at any time. While renting presents a flexible option to access equipment, their availability may heavily depend on the demand from other renters.

Crucial for Large-Scale Projects

Buying equipment ensures businesses are well-positioned for any large-scale projects. Investing in and regularly using large equipment like bulldozers and excavators, as well as specialized equipment, can help companies save on costs throughout these longer-term projects.

When It Makes Sense to Buy Construction Equipment

Renting construction equipment is a viable option for many companies, especially when considering factors like upfront costs, depreciating value, and storage costs. However, there are times when buying equipment would be a better option overall. These include when:

- The equipment will be regularly used: If the equipment will be used often, then it’s best to pursue the purchase option. As a general rule of thumb, if the equipment is used more than 65% of the time, you should buy it. For construction excavators, it’s a good idea to purchase one if it will be used more than 175 hours a year.

- Handling long-term projects: Buying is also a more cost-effective, convenient option if a business is looking at a long-term construction project. Long-term projects require flexibility and consistent utilization of equipment. Renting confines the user and may stall the project, depending on the demand for the rental equipment.

- Specialized construction equipment is needed: Specialized equipment may be even less available for rental, causing significant project delays. Buying specialized construction equipment is better than renting especially if they’ll be needed frequently.

Rental Construction Equipment From Central Diesel

Deciding to buy vs. rent construction equipment depends on the company’s current construction projects, budget, and long-term plans. Renting allows businesses to avoid high upfront and maintenance costs, while buying construction equipment is a more convenient, cost-effective long-term option in certain cases, such as for large-scale projects.

Central Diesel has more than 50 years of experience offering diesel engines and other products to the construction industry. Our equipment is designed to reduce emissions and fuel consumption while providing optimal power to construction equipment. Our dedicated service has enabled us to serve more than 4,000 clients across various industries. To learn more about buying and renting construction equipment and which option best fits your needs, contact us today.

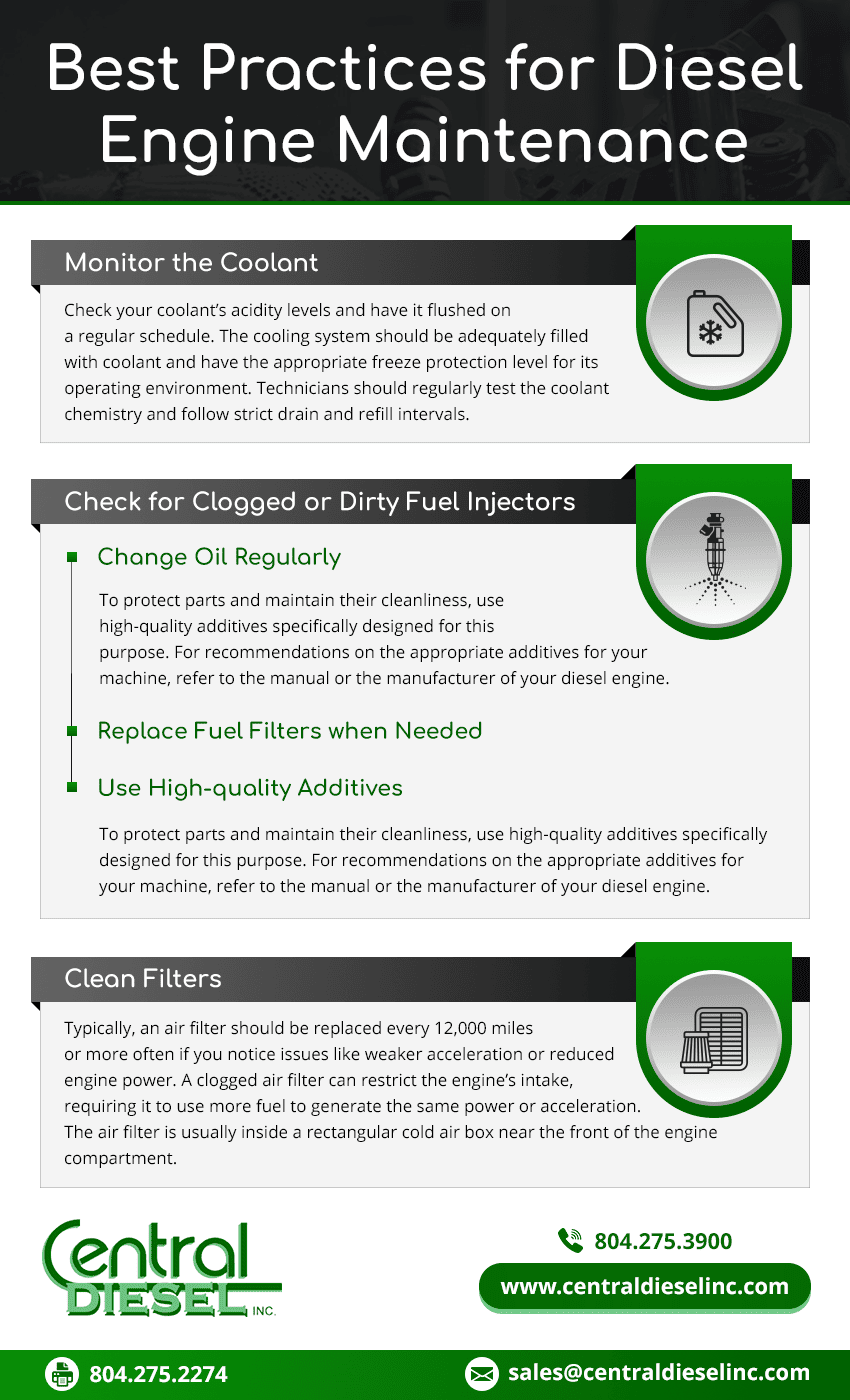

Best Practices for Diesel Engine Maintenance

Leave a CommentDiesel engines are widely used in automobiles, generators, marine vessels, industrial machinery, and more. They are known for their durability, efficiency, and power. However, like any other type of engine, diesel engines require regular maintenance to ensure optimal performance and longevity. Implement these best practices for diesel fuel system maintenance to prevent breakdowns, reduce repair costs, and extend the engine’s life.

Monitor the Coolant

Regularly monitoring your diesel engine’s coolant is critical for optimal engine performance. Over time, the coolant becomes more acidic and can corrode other cooling system parts, such as the radiator. Check the coolant’s acidity levels and have it flushed on a regular schedule.

Moreover, make sure the cooling system is adequately filled with coolant and has the appropriate freeze protection level for its operating environment. Failure to do so can cause overheating and corrosion or result in the coolant freezing and expanding, causing passages or lines to crack.

Low coolant levels likely indicate loose or worn hoses or leaking radiator. Sometimes it may be caused by head gasket leakage, which can eventually contaminate the engine oil and cause engine failure. Tier IVF and IVi engines should be checked for nitrogen reduction system (NRS) and exhaust gas recirculation (EGR) cooler leaks. These leaks present as a slow, constant loss of coolant, and if left unchecked, they can damage the diesel particulate filter, intake, and intake valves.

To maintain proper coolant levels and properties, technicians should regularly test the coolant chemistry and follow strict drain and refill intervals. Your coolant supplier can also be a valuable resource for verifying the effectiveness of your chosen preventive maintenance procedures.

Check for Clogged or Dirty Fuel Injectors

Maintaining clean fuel injectors and diesel fuel is crucial to keeping diesel engines running smoothly. Diesel fuel is more viscous than gasoline and can more easily hold dirt and debris in suspension. When injectors are clogged or dirty, the fuel may not spray properly in a fine mist, causing the engine to skip or completely stop.

Here are some signs that your diesel injection systems are dirty or clogged:

- Black smoke from the exhaust manifold

- Hard starting

- Rough idling

- Pinging sounds

- Throttle hesitation

- Increased fuel consumption

- Poor engine performance

To keep diesel fuel injection systems clean, it’s essential to:

- Change oil regularly: Oil picks up contaminants from the engine, leading to buildup on the fuel injectors. Regular oil changes remove this buildup and ensure the engine runs smoothly and efficiently.

- Replace Fuel Filters when needed.

- Use high-quality additives: To protect parts and maintain their cleanliness, use high-quality additives specifically designed for this purpose. For recommendations on the appropriate additives for your machine, refer to the manual or the manufacturer of your diesel engine.

If the engine exhibits irregular running, rapping, or black smoke, the spray nozzle valves may be clogged or held open due to dirt particles. This can cause inefficient fuel combustion, leading to poor performance and black smoke.

Clean Filters

Diesel engines commonly have two fuel filters: A primary filter between the fuel tank and engine and a secondary filter between the fuel injectors and transfer pump. Diesel fuel, being less refined, absorbs the extra water from condensation in the tank. Water in the fuel can cause several problems, including reduced fuel efficiency and engine stalling. This is why manufacturers build diesel engines with two fuel filters and sometimes three.

Regularly changing air filters also ensures your engine runs smoothly. The air filter is usually inside a rectangular cold air box near the front of the engine compartment. A clogged air filter can restrict the engine’s intake, requiring it to use more fuel to generate the same power or acceleration. Typically, an air filter should be replaced every 12,000 miles or more often if you notice issues like weaker acceleration or reduced engine power.

Schedule Your Diesel Engine Maintenance Today with Central Diesel

Following best practices for diesel engine maintenance can save you time and money by preventing unwanted downtime. It also ensures that your diesel engine runs efficiently, reducing fuel consumption.

At Central Diesel, we specialize in diesel engine maintenance and repairs. Our technicians provide comprehensive diesel fuel maintenance services tailored to your specific needs. We use the latest diagnostic tools and equipment to identify potential issues before they become major problems. Request a quote or contact us today to learn more about our diesel engine maintenance services.