Diesel engines are a type of compression-ignition engine known for their high-performance and robust machinery. Unlike gasoline engines that use spark plugs, diesel engines compress air and inject fuel directly into the compressed air at high pressure. The heat generated by the compressed air ignites the diesel fuel spontaneously, causing it to burn and drive the engine’s pistons. Although known for their inherent durability, diesel engines require proper maintenance and proactive repair to unleash their full potential.

Central Diesel, Inc. specializes in a comprehensive range of diesel engine repair and maintenance services. We also offer premium engine parts, including top-quality generators, fuel injection systems, filtration and exhaust systems, turbocharger assemblies, and electrical components.

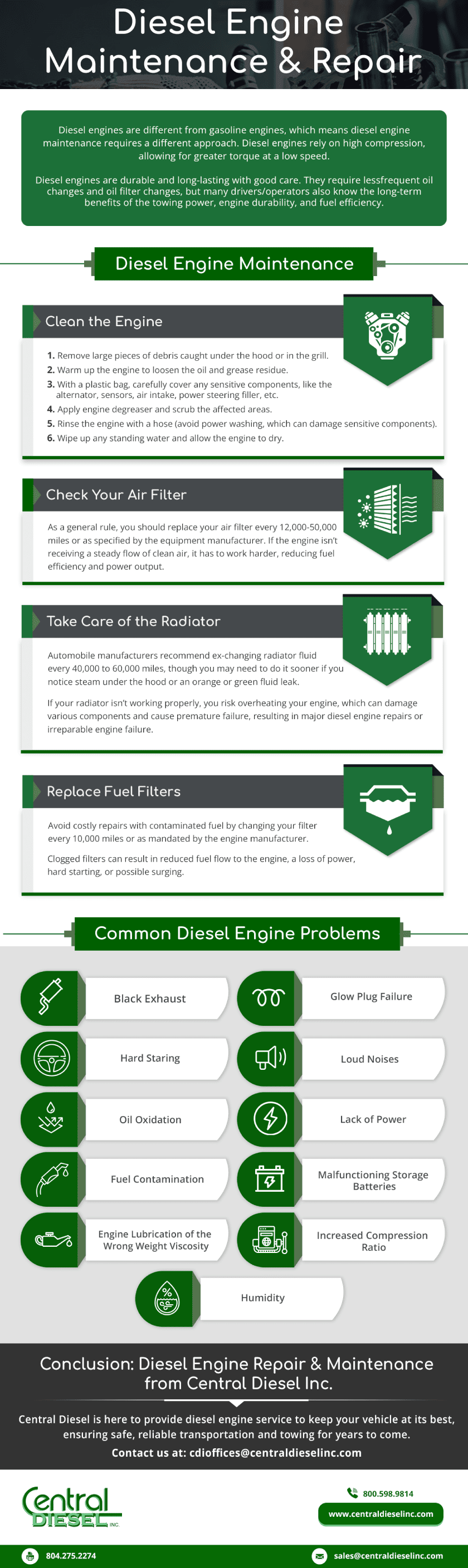

Common Diesel Engine Problems

Identifying diesel engine problems early on can prevent major repairs. Some prevalent issues include:

- Black exhaust: This may indicate an imbalance of air-to-fuel proportions, possibly linked to issues with the air filter, injector, turbocharger, or EGR valve.

- Glow plug failure: If you face difficulties starting your vehicle in cold weather, worn-out glow plugs might be the culprit.

- Hard starting: This issue could signal low engine compression, problems with the fuel delivery system, or a worn-out battery.

- Unusual noises: While diesel engines are naturally louder than gasoline engines, unusual noises may indicate problems with fuel injectors or low engine oil levels.

- Oil oxidation: Air entering the oil system can disrupt proper lubrication, a common occurrence if a vehicle remains unused for an extended period.

- Lack of power: Reduced power output may result from various issues, such as clogged fuel filters, problems with throttle linkage or fuel injectors, or excessive lubrication.

- Increased compression ratio: While high compression ratios contribute to powerful, smooth-running engines, they can also interfere with fuel injection performance and lead to more frequent engine knocking.

Diesel Engine Repair and Maintenance From Central Diesel, Inc.

We are a full-service repair shop for diesel engine solutions. Here’s an overview of the services we provide:

Maintenance

Our proactive approach to diesel engine maintenance includes periodic engine cleaning that addresses issues stemming from dirt and grease. We also handle timely routine servicing, such as oil and filter changes, which are crucial for maintaining fuel efficiency and optimal power output.

Repairs

At the core of our expertise lies diagnostic proficiency, allowing us to swiftly identify and resolve diesel engine problems. Our repair shop is equipped to handle everything from routine parts replacement to intricate repairs of electrical systems. We also specialize in fuel system repairs, ensuring consistent fuel flow and preventing power loss.

Rebuilds

For engines needing extensive attention, our rebuild services go beyond repairs, encompassing thorough inspections, replacements, and overhauls to restore optimal functionality. We are certified dealers of high-quality diesel engines, generators, and related parts to ensure reliability in every aspect of your engine needs.

Why Choose Us?

Here’s why you should entrust your diesel engine maintenance and repair to us:

Decades of Expertise

With a legacy dating back to 1972, Central Diesel, Inc. brings years of invaluable experience to clients. Our long-standing presence in the industry attests to our expertise and reliability in diesel engine repair.

Brand Diversity

Our technicians are well-versed in the intricacies of diverse diesel engines, ensuring expertise across top engine providers. We cater to various brands, such as Mitsubishi, Deutz, Perkins, Cummins, Isuzu, Kubota, Kohler and more.

Quality Testing Equipment

Central Diesel, Inc. employs the same testing equipment as original equipment manufacturers (OEMs). This commitment to using top-tier technology underscores our dedication to delivering precision and reliability in every service.

Global Reach

We have established an international presence serving clients worldwide. Our services extend to diverse sectors, including agriculture, construction, industrial, mining, transportation, marine, government, and military.

State-Of-The-Art Facilities

Our advanced facilities are equipped with cutting-edge tools and technologies. Therefore, clients are guaranteed to receive the highest standard of diesel engine repair and maintenance services.

Partner With Central Diesel, Inc. for Unmatched Diesel Expertise

Unleash the full potential of your diesel engines with Central Diesel, Inc.’s unmatched expertise in repair and maintenance! Since 1972, we have become a trusted name in the industry, serving over 4,000 loyal customers. Our expert team is ready to optimize your engine’s performance from timely maintenance to high-quality assemblies and part replacements.

Your engines deserve the best, and we deliver excellence every time! Contact us or request a quote to get started.