When comparing diesel and gasoline engines, diesel engines are ultimately considered superior to gas engines in heavy-duty vehicles because of their improved fuel efficiency and longer life expectancy. They are often the preferred engine type for vehicles such as emergency vehicles, bulldozers, dump trucks, excavators, ships, semi-trucks, and trains.

Diesel vs Gas: Understanding the Differences

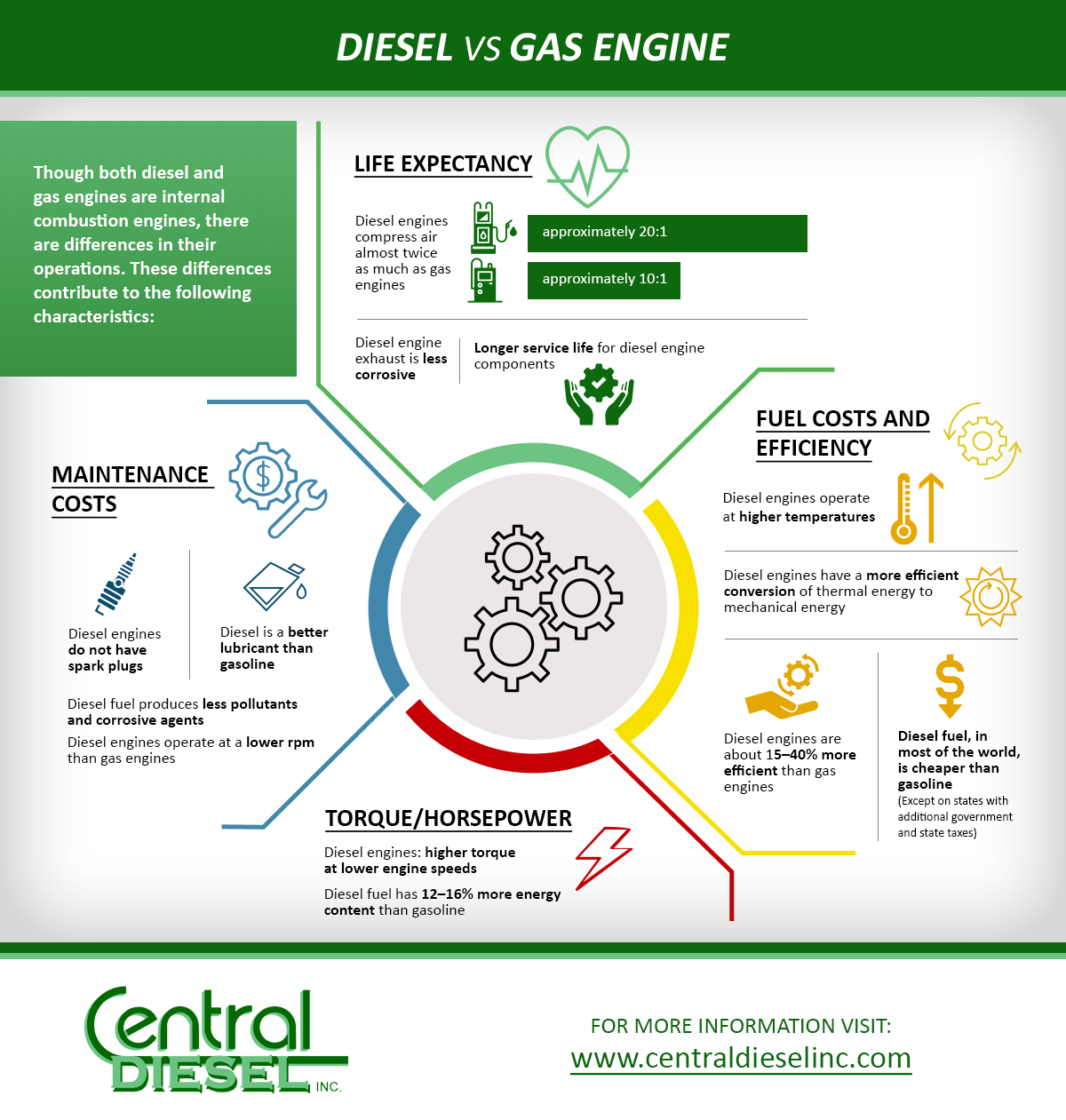

Though both diesel and gas engines are internal combustion engines, there are differences in their operations that make diesel engines more suitable for industrial vehicles. The differences come from:

- The higher energy density of diesel fuel

- The greater compression of air by diesel engines

- The absence of spark plugs in diesel engines

These differences contribute to the following characteristics:

- Life expectancy. Diesel engines compress air almost twice as much as gas engines (approximately 20:1 vs 10:1). As such, engine parts like block and cylinder heads, crankshafts, pistons, and valves in diesel engines are designed to be more robust than gas engines. This higher compression also results in more complete combustion of the fuel than what is found in gas engines, so diesel engine exhaust is less corrosive. This contributes to a longer service life for engine components.

- Fuel costs and efficiency. Due to increased air compression, diesel engines also operate at higher temperatures than gasoline engines. This results in a more efficient conversion of thermal energy to mechanical energy. Diesel engines are about 15–40% more efficient than gas engines and diesel fuel is about 15% cheaper than gasoline. Therefore, the per-mile cost of diesel engines is significantly lower than gas engines.

- Torque/horsepower. The high compression ratio of diesel engines gives them an ability to create a higher torque at lower engine speeds. Also, diesel fuel has 12–16% more energy content than gasoline. These factors make diesel engines ideal for heavy load applications that require a steady, high torque.

- Maintenance costs. Diesel engines do not have spark plugs. Diesel is also a much better lubricant than gasoline. When considering emissions from diesel versus gasoline, the more complete ignition of the diesel fuel produces less pollutants and corrosive agents. Diesel engines operate at a lower rpm than gas engines. All these factors contribute to reducing the maintenance costs for diesel engines.

The Importance of Proper Engine Maintenance

Diesel fuel easily picks up contaminants due to its high viscosity. Periodically changing the oil and oil filter will clean accumulated dirt from inside the engine. It is also important to keep an eye on oil consumption as an early indicator of harmful oil leaks. These should be quickly detected and promptly fixed.

Diesel engines require a steady supply of clean air to maintain peak performance. Dirty filters reduce airflow to the engine, so it is important to regularly inspect and change air filters. This is especially important for dump trucks, military vehicles, and boats that operate in harsh environments.

Quality Diesel Engine Services from Central Diesel

Central Diesel offers troubleshooting and restoration services for damaged or malfunctioning diesel engines. Our experienced staff can help you to identify and correct problems with your diesel engines before they result in engine failure and costly replacement.

We are a diesel engine specialist and have been supplying parts and providing maintenance services to government agencies, the military, and heavy industries like mining and agriculture for over 45 years. Please contact us or submit a request for a quote for assistance with your diesel engine maintenance and repair needs.